E beam lithography is a fantastic technological innovation that uses electrons to change the sub-atomic condition of a targeted material or surface. In the ebeam interaction, clouds of electrons are produced inside a vacuum chamber, which at that point are sped up through a flimsy, metallic foil window and are directed onto a moving printed web surface. The adhesives, inks, or coatings that respond to ebeam are comprised of sub-atomic components known as monomers and oligomers. These sped-up electrons associate these atoms into longer-length polymers, quickly changing their original chemical state from a wet state into a dry or strong state.

The process of ebeam lithography sterilization utilizes high-power cutting edge accelerators to make an amazing beam of electrons.The beam is filtered to and fro to make a line of quick electrons, which shower and securely ionize the materials that they strike. There is no radioactivity included. In this process of e beam lithography, boxes of clinical tools are put on a mode of transport in a separate layer. As the beam is passed through them, the electrons enter the cardboard box and every clinical tool in their individual bundles inside the container. Hazardous microorganisms are totally inactivated with insignificant impact on clinical tools.As the electrons infiltrate the items, the radiation extent reduces so less radiation leaves the container that it entered.The medical tools are irradiated from their opposite side to get a moderately uniform dose. The best part about his process is that the Ebeam machine used by lithography companies is exceptionally reliable and provides good radiation sterilization as the dosing provided can be reused.

What are the advantages of E beam sterilization process?

E-beam sterilization has numerous benefits such as:

- It is helpful, delicate, and efficient.

- E-beam sterilization can be performed constantly on items in their final package.

- Contrasted with steam sterilization, it works at a much lower temperature and is good to use for items having hard-to-reach zones (e.g., covered cartridges).

- Contrasted with gamma irradiation, it represents a much lower hazard of degradation(because of more limited exposure times).

- contrasted with ethylene oxide exposure, it disposes of the danger of ethylene oxide ingestion and ensuing draining into drug item.

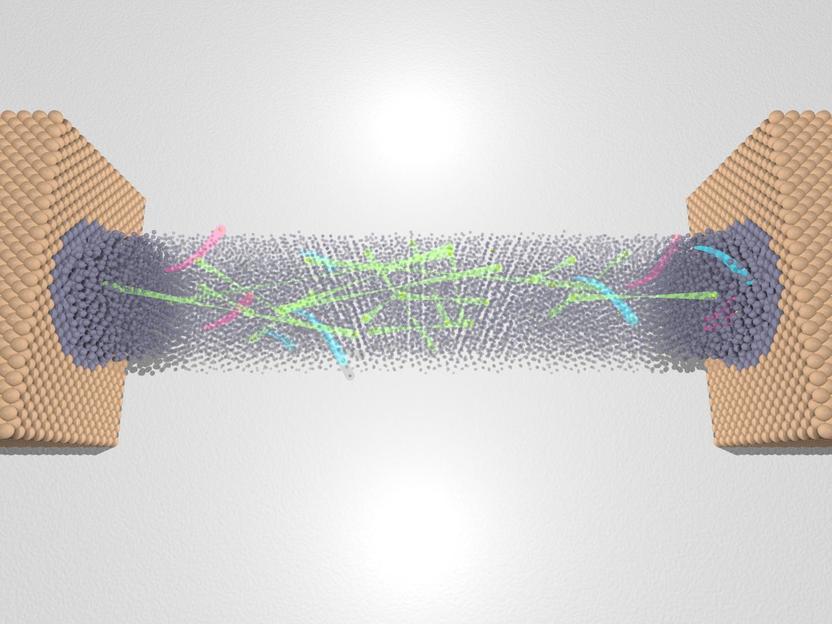

Electron beam welding is a revolutionary fusion welding technique. Electrons are created (through an electron weapon) and afterward sped up to high velocities using electrical fields. This fast stream of electrons is then made to focus using magnetic fields and carefully applied to the materials to be joined. As the electrons sway the materials their motor energy is changed over to heat energy, which makes the metals liquefy and stream together. Electron beam welding usually happens in a vacuum as the presence of gas atoms can disperse the beam easily. Electron beam welders are extremely costly, should be firmly maintained, and the help needed by the high voltage and high vacuum technologies can sometimes be very demanding.

What are the benefits of Ebeam welding technique?

The electron beam welding technique is an exceptionally precise procedure and is likewise repeatable because of the automation.This welding technological innovation additionally makes solid and pure joins that can be utilized across various top applications for a wide scope of businesses. Electron beam welding additionally offers exact weld infiltration control from a depth as little as 0.0001 inches. The EB cycle likewise gives a little heat-influenced zone because of the great depth to-width proportion, which limits distortion and material shrinkage while permitting welds to be acted in proximity to warm delicate segments. Electron beam welding likewise shows high strength properties, keeping up to 95% of the strength of the base materials. The process is acted in a vacuum environment, there are no contaminations left after the process. Oxides and nitrides are dispensed while pollutants in the actual materials are disintegrated. EB welding is likewise exceptionally mechanized and subsequently controllable, while additionally being incredible for joining materials, like refractory or dissimilar metals, that are not weldable with regular cycles.

Powerful electron beam systems for welding and penetrating are used in Aerospace, Automotive, Defense, Semiconductor, Medical, Nuclear, Oil and Gas, Power Generation and an assortment of different businesses. The present airplane have parts that were produced using EB Welding. All throughout the planet, automobile parts are produced utilizing EB Welding.

Customers report great outcomes from using the Electron Beam Welding technique on a wide scope of projects. However, the accomplishment of a weld depends on the actual technique, the plan, surface arrangement, and materialness used in a specific project. This is a crucial decision, so it is worth inspecting how EB welding functions, the necessities for progress, and how the process varies from other options.

If you are finding e beam lithography companies near you, visit http://sts-elionix.com/ for information.