At RADMOT, we pride ourselves on delivering high-quality CNC turning services tailored to meet the needs of a variety of industries. Our commitment to precision and our expertise in producing custom machined parts are what set us apart in today’s dynamic industrial landscape. CNC turning is a critical process that allows us to create components with exceptional accuracy, helping our clients achieve their production goals efficiently and effectively.

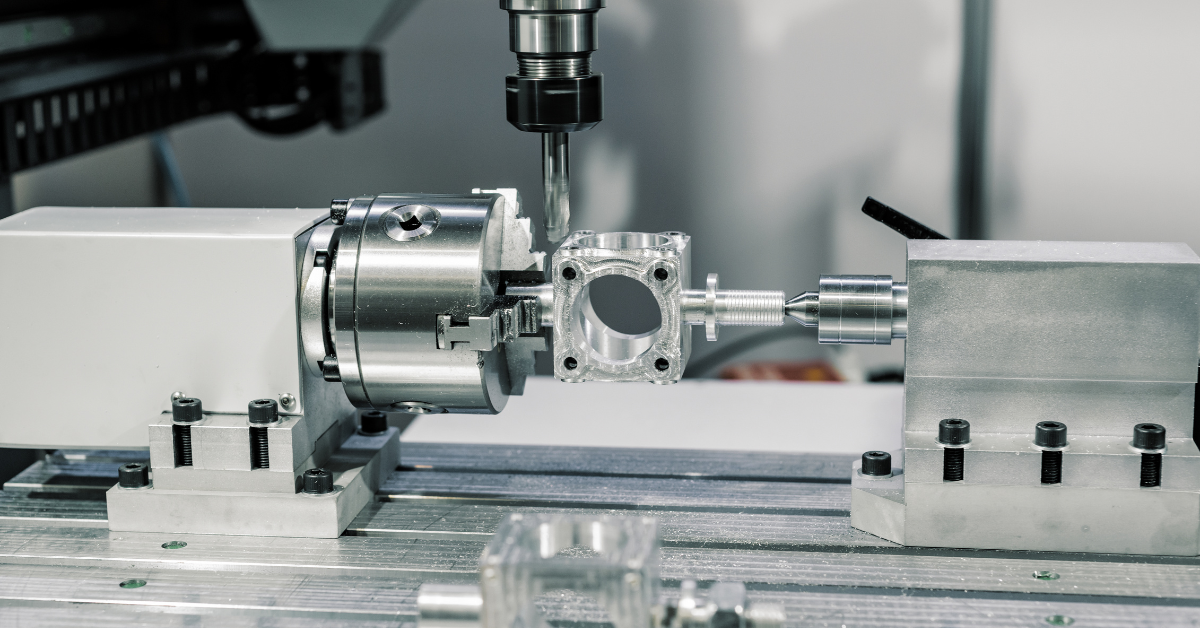

CNC turning involves the use of computer-controlled machines to rotate a workpiece against a cutting tool. This process allows us to shape materials into intricate designs and specifications. At RADMOT, we use state-of-the-art CNC turning machines that are programmed to perform complex cuts and shapes, ensuring that each part is manufactured to the highest standards. Our skilled technicians oversee the entire process, from programming the CNC machines to the final inspection of each part. This meticulous attention to detail guarantees that our clients receive components that not only meet but often exceed their expectations.

One of the standout features of our CNC turning services is our versatility. We work with a broad range of materials, including metals, plastics, and composites. This flexibility allows us to serve a diverse array of industries, such as automotive, aerospace, medical, and consumer goods. Whether you need a small batch of custom parts or large-scale production, our team at RADMOT is equipped to handle projects of any size. Our focus is always on delivering high-quality results while maintaining competitive lead times and cost-effective solutions.

Understanding the CNC Turning Process

To fully appreciate the value of our CNC turning services, it is important to understand the turning process itself. CNC turning begins with a design, typically created in CAD (Computer-Aided Design) software. This design is then translated into a CNC program that dictates how the machine will operate. Our engineers work closely with clients to understand their specific needs and translate these requirements into precise programming.

Once the program is set, the CNC turning machine takes center stage. The workpiece is mounted securely in the machine, which then rotates it at high speeds. As the material spins, a cutting tool moves along the length of the workpiece, removing excess material and forming the desired shape. The result is a highly precise component, often with tight tolerances that can meet even the most stringent specifications.

After the turning process is complete, each part undergoes rigorous quality control checks. Our quality assurance team inspects the finished components using advanced measurement techniques and tools. This step is crucial to ensuring that every part meets our high standards and complies with industry regulations. By investing in quality control, we can guarantee that our clients receive reliable and durable components that will perform well in their applications.

Collaborating with RADMOT for CNC Turning Services

At RADMOT, we believe that successful collaboration begins with clear communication. When clients choose to work with us for their CNC turning needs, they can expect an open and transparent dialogue throughout the project. We take the time to understand your objectives, preferences, and any specific challenges you may be facing. This collaborative approach allows us to provide tailored solutions that align with your business goals.

Our project management process is designed to keep you informed every step of the way. From initial design discussions to the final delivery of your parts, we ensure that you have access to updates and insights. This proactive communication fosters trust and helps prevent misunderstandings, making the entire experience smoother and more efficient. Our team is always available to address any questions or concerns, ensuring that you feel supported throughout the entire process.

In addition to our commitment to quality and communication, we also prioritize flexibility. We understand that project requirements can change, and timelines may shift. Our agile approach allows us to adapt to these changes while still delivering high-quality CNC turning services on schedule. Whether you need to adjust the design or modify the order volume, our team is ready to accommodate your needs.

Why Choose RADMOT for Your CNC Turning Services?

Choosing the right partner for CNC turning services can significantly impact your project’s success. At RADMOT, we combine cutting-edge technology with industry expertise to provide unparalleled services. Our skilled team has years of experience in CNC machining and understands the complexities involved in creating custom parts. We are dedicated to using the best practices in the industry to ensure that our clients receive parts that are not only accurate but also cost-effective.

Additionally, our investment in modern machinery and software sets us apart from competitors. We continually upgrade our equipment and technology to remain at the forefront of the industry. This commitment to innovation enables us to offer advanced solutions and optimize our production processes, ultimately benefiting our clients. When you choose RADMOT, you can rest assured that you are partnering with a company that values excellence and strives to deliver the best possible results.

In conclusion, if you are in need of high-quality CNC turning services, look no further than RADMOT. Our dedication to precision, commitment to quality, and customer-focused approach make us an ideal choice for your machining needs. We invite you to learn more about our services and how we can support your next project by visiting our website at radmot.com. Let us help you bring your ideas to life with our expert CNC turning capabilities.