The EBL or Electron Beam Lithography is the process to form a small pattern with the electronics with the result as the integrated circuits. The current is nothing but the movement of the electrons. The size of the electrons is of very small size, and the wavelength of the light controls the resolution of the optical lithography. The wavelength of an electron is very small due to its small size, and the diffraction doesn’t allow the lithographic reaction.

When we talk about E beam lithography, there are advanced technologies and techniques for maskless lithography. The electron beam lithography is nothing but one of the basic forms of maskless electron beam lithography. The advanced E beam lithography is interference lithography, dip-pen lithography, ion beam lithography, etc. The beam lithography is applicable in multiple research and based organizations. One such field is nanotechnology that uses this to form a high-resolution pattern.

Actually, the electron beam lithography (EBL) can be expanded beyond the diffraction, and the small wavelength of the electrons can be more applicable in research. Technically, it is in picometer units. In beam lithography, a small resistance is imposed by electrons. This resistance can be highly effective in shaping the right results. All these factors are collectively responsible for achieving the highest resolution in the electron beam lithography system. Various methyl methacrylate-based resistance is advised to be used during the entire process.

Electron beam lithography comes with advantages and applications. The following industries and sectors are highly benefited from the lithography techniques:

- It is used in pyroelectric devices.

- It is used for optoelectronics devices.

- Quantum physics has usage of electron lithography

- It can be used in multiple investigations related to the transparent mechanism

- It is used in semiconductors

- It is used in superconductors

- It can be used in microsystem techniques

- It can be used in optical instruments.

These are some of the industrial usages of electron beam lithography. But, there are other fields as well that can make up for this list.

How does Electron Beam Lithography work?

Now you must have got the idea of what exactly is e beam lithography, and it’s time to move one step forward. Let’s explore how the entire process is carried out:

As per various lithography companies, the functioning of electron lithography is based on a very basic concept. If we compare photo-lithography and electron beam lithography, you will find certain similarities between the two. An electron compatible substance is introduced in the focused electron beam, and hence the scanning is done. The substance solubility level acts as per the electron beam energy. The electrons are scattered all along the surface of the substance. All the areas/regions of the substance that are not exposed to the electrons can be eliminated easily.

Nowadays, a lot of modern electron beam lithography techniques are available in the market. The depth of the research results can go up to hundreds of nanometers. All these advanced systems use robust technologies and can be overpowered to deal with certain fluctuations. The contemporary electron lithography allows you to provide huge designs at a unified manufacturing level. Hence, modern electron lithography can handle the topology of the GaN with a set of exceptional results.

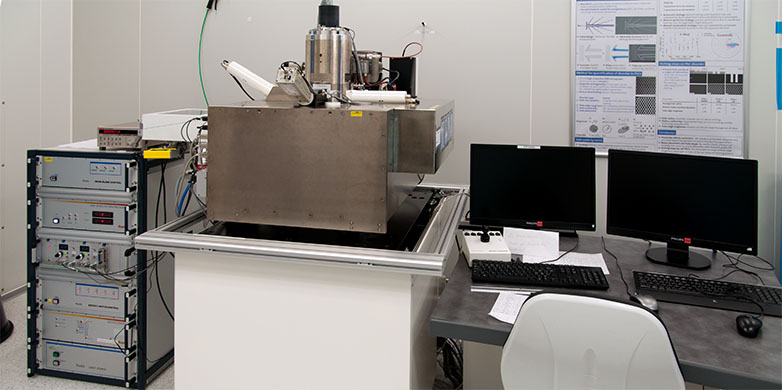

Electron beam lithography is a very time taking process and expensive as well. Also, it is much slower than other processes like photo-lithography and stamping. With the scanning electron microscope, this e beam lithography can provide effective results with high-resolution patterns. The electron beam lithography has a much higher resolution with a better pattern than any normal lithography. The shorter wavelength of the electrons is responsible for this precision.

Bottom Line:

We aim to make you completely aware of electron lithography. The above details and research is done with various industry expertise results. This can surely expand the scope of the topic and assist you in understanding how e beam lithography can be helpful in conducting research.

The experiments with electron beam lithography are done with utmost care. All the steps are very crucial and must be performed with extensive details. We have tried to cover all the fundamental aspects of electron lithography and hope to provide the most important technical knowledge related to the subject.

There are certain e beam lithography companies in the market that can provide the perfect lithography equipment. Along with that, you can avail the right set of experiment details and research assistance. The scanning electron microscopes provide electron lithography and its techniques. In order to categorize and differentiate the systems, the beam shape and deflection system are the prominent factor to find the right outcomes.

We hope the above-shared information proves helpful to you in future research.